In recent years, there has been growing interest in surface induction hardening—a modern heat treatment technology that significantly improves the quality and durability of machine and tool working surfaces. Contemporary equipment used in this process is becoming increasingly energy-efficient, primarily due to the use of energy-saving power supplies and advanced automatic control systems.

Simultaneously, the technical expertise of manufacturers of high-quality gearboxes and gears is advancing, resulting in numerous improvements, including noise reduction, weight reduction of components, and lower production costs. One of the key objectives of induction hardening for gear applications is to obtain a suitably hardened surface layer characterized by enhanced wear resistance.

By enabling the formation of a favorable martensitic structure, induction hardening often allows the substitution of expensive high-alloy steels with cheaper medium- or high-carbon steels, or low-alloy steels, without compromising the required operational properties.

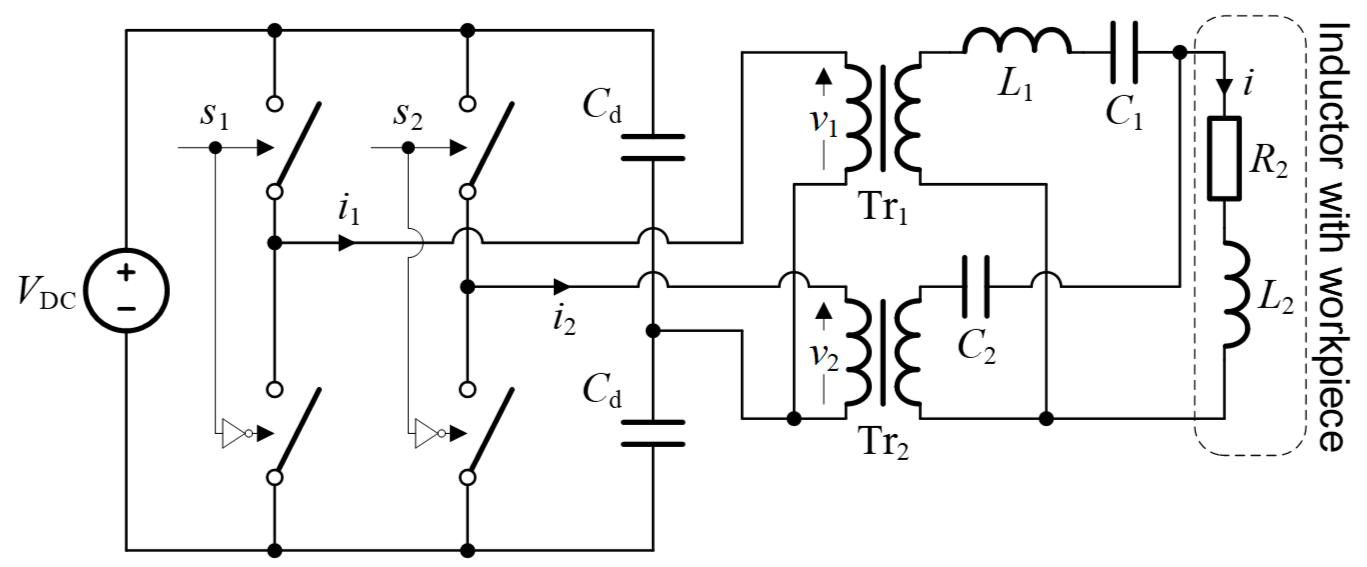

The objective of the project is to develop an induction heating system for surface hardening. Due to its modular design and efficient shaping of the temperature field distribution, the device is intended to enable surface hardening over a wide frequency range: (10–30) kHz for medium frequency (MF) and (100–300) kHz for high frequency (HF), with power up to 100 kW. This will allow hardening of components with:

• varying degrees of shape complexity;

• a wide range of diameters;

• a wide range of hardened layer depths.

The system design will be based on patents 241666 and 245362. The essential feature of this device is that, owing to a simplified construction with respect to the number of power converters and passive resonant circuit elements, it enables independent control of the medium frequency (MF) and high frequency (HF) power components, for example using a frequency-based (FM) method. This capability applies both to simultaneous dual-frequency (SDF) heating and to pulsing dual-frequency (PDF) heating modes.